| Crash reported at 1100Z |

| Metars (Bagram, via US Military): |

| KQSA 291255Z 04008G16KT 9000 -TSRA BKN050CB BKN090 BKN150 09/05 A3003 RMK CB NE MOV NE SLP181 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 291231Z 30009G16KT 8000 -TSRA BKN050CB BKN090 BKN150 08/04 A3001 RMK CB NE MOV NE WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 291229Z 30010G15KT 6000 -TSRAGS BKN050CB OVC100 12/04 A3000 RMK CB OHD MOV N WND DATA ESTMD LSTG/SLP ESTMD= |

| KQSA 291155Z 33008G17KT 9999 -TSRA SCT050CB BKN090 BKN170 13/04 A2996 RMK CB OHD MOV N SLP139 60000 70000 51014= |

| KQSA 291155Z COR 33008G17KT 9999 -TSRA SCT050CB BKN090 BKN170 13/04 A2990 RMK CB OHD MOV N SLP139 WND DATA ESTMD ALSTG/SLP ESTMD 60000 70000 51014= |

| KQSA 291059Z 35011G17KT 9999 FEW050 BKN065 BKN090 14/05 A2993 RMK WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 291058Z 35011G17KT 9999 FEW050 BKN080CB BKN150 14/05 A2993 RMK LTG DSNT NW SLP124 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 291055Z 02007KT 9999 FEW040 BKN080CB BKN150 18/06 A2994 RMK PK WND 06026/1005 WSHFT 1027 LTG DSNT NW CB DSNT NW SLP124 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290955Z COR 10017G30KT 9999 SCT085 BKN140 BKN200 17/06 A2992 RMK PK WND 09032/0856 LTG DSNT NW CB DSNT E SLP213 WND DATA ESTMD ALSTG/SLP ESTMD COR 13= |

| KQSA 290855Z 09026G37KT 6000 -TSRA DU FEW000 BKN070CB BKN130 17/06 A2990 RMK PK WND 09037/0852 CB W SLP103 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290755Z 12025G37KT 9999 SCT032CB BKN070 BKN150 17/06 A2995 RMK PK WND 10037/0747 CB W MOV N SLP114 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290655Z 12015G27KT 9999 VCTS SCT036CB BKN050 BKN080 15/08 A2998 RMK CB N MOV N SLP135 WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290630Z 12016G24KT 5000 -TSRAGS FEW030 BKN050CB 15/07 A3000 RMK CB OHD MOV N WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290628Z 10015G20KT 9999 -SHRA SCT043 BKN050 BKN080 16/06 A3000 RMK LTG DSNT SE WND DATA ESTMD ALSTG/SLP ESTMD= |

| KQSA 290555Z 31007KT 9999 BKN050 15/04 A3001 RMK SLP134 WND DATA ESTMD ALSTG/SLP ESTMD 58010= |

| Metars (of Kabul 22nm south of Bagram): |

| OAKB 291350Z 18004KT 7000 BKN050 13/04 Q1016 NOSIG RMK BLU BLU |

| OAKB 291250Z 30007KT 9999 SCT040CB BKN060 15/01 Q1015 NOSIG RMK BLU BLU |

| OAKB 291150Z 10017G27KT 9999 VCTS SCT090CB BKN120 16/06 Q1013 NOSIG RMK BLU BLU |

| OAKB 291050Z 11020G30KT 9999 SCT090 OVC120 16/05 Q1012 NOSIG RMK BLU BLU |

| OAKB 290950Z 10020G30KT 9999 SCT080CB 17/06 Q1012 NOSIG RMK BLU+ BLU+ |

| OAKB 290850Z 10025G42KT 9999 FEW060CB SCT070 17/05 Q1013 NOSIG RMK BLU+ BLU+ |

| OAKB 290750Z 11020G30KT 9999 BKN060 17/06 Q1014 NOSIG RMK BLU BLU |

| OAKB 290650Z 10017KT 9999 FEW050 BKN060 16/05 Q1015 NOSIG RMK BLU BLU |

The crash was caught on film by a dashboard video camera in a vehicle operating on perimeter of the airfield. The film was posted on You Tube and immediately went viral - 747 Crash

Within hours after the crash, an account was posted on an Internet aviation "news" site that claimed that the crew had made a radio call to the tower and reported that their load had shifted, however this has not been verified. Furthermore, the company, National Airlines, put out the following statement which makes the possibility of a load shift remote.

A note regarding the video - while it appears that the airplane is in an excessive noseup attitude, this is possibly an optical illusion. The vehicle and the airplane were closing on each other from opposite directions at a high rate of speed. This can create a false impression of nose up angle.

Statement from National Air Cargo

National Air

Cargo will not speculate as to the cause of the accident involving National

Flight NCR102. With our full cooperation, an investigation by appropriate

authorities is under way, and we encourage everyone to join us in respecting

that process and allowing it to take its appropriate course.

Here are some

facts regarding the aircraft and its movements prior to the

accident: ·

National Flight NCR102 was en route to Dubai from Camp

Bastian and had stopped to refuel at Bagram Air Base. ·

The cargo contained within the aircraft was properly loaded

and secured, and had passed all necessary inspections prior to departing Camp

Bastian. ·

The aircraft landed safely and uneventfully in

Bagram. ·

No additional cargo or personnel was added during the stop

in Bagram, and the aircraft’s cargo was again inspected prior to departure.

Please visit

www.nationalaircargo.com for updates regarding this tragic accident. Media

inquiries can be directed to publicrelations@nationalairlines.aero. |

At this point let me state my qualifications to comment on this terrible accident:

1. From 1964 to 1975 I was a loadmaster in the US Air Force on C-130, C-141 and C-5A aircraft. As the name implies, I was trained and qualified to supervise the loading and restraining of cargo on transport airplanes. During those eleven years, I logged over 6,500 hours flying time on cargo flights all over the world and made literally hundreds of cargo onloads.

2. After leaving the Air Force in 1975, I became a professional pilot and logged some 17,000 hours of flying time, more than half of which was in transport category airplanes. I hold an Airline Transport Rating with two type ratings and am a certificated flight instructor for airplanes and instruments. At one time I taught aerobatics.

3. For a year and a half, I was a simulator instructor for Flight Safety, Incorporated at the Houston, Texas Center at Houston Hobby Airport. While working for Flight Safety, I was informed that my training records showed that I had attended ground school and simulator training at Flight Safety Centers more than twenty-five times, which means I had completed close to 100 simulator training sessions. During the times I trained at Flight Safety and at other companies, in nearly every case I received training on recognizing and peforming escape maneuvers from violent windshear pheneomena. As a simulator instructor, I administered wind shear training, with an emphasis on microbursts, to every client I trained.

There were two accidents involving Douglas DC-8 transports that were initially believed to have been caused by a load shifting on takeoff but were found to have been due to something else.

1. The first of these was at Miami International where a DC-8 operated by a company called Fine Air crashed immediately after takeoff in August 1997. The accident was found to have been caused by an out of limits center of gravity combined with the pilots having been provided erroneous weight and balance data, which led to them using the wrong takeoff setting for the aircraft stabilizer. Although a number of cargo locks were found to have been improperly secured, they were not found to have contributed to the crash. The load was not believed to have shifted prior to the impact.

2. The second accident was at the former Mather Air Force Base at Rancho Cordova, California. An Emery Air Freight crew reported that they were experiencing an extreme aft CG right after takeoff. The crew attempted to return for a landing but the airplane stalled and crashed during their attempt. The accident investigation board determined that the cause of the crash was a disconnection of the right elevator control tab. They did not have an extreme aft CG, they had a control problem.

In the video of the Bagram crash, the 747 is shown impacting the ground in a nose-low attitude and almost in level flight. (Some who have seen it have the idea that the crew had some control over the airplane but this is unlikely since the time from the stall to impact is only six seconds.) In the Miami crash, the DC-8 struck the ground tail first, followed by one of the wings. This is commiserate with an impact by an airplane with an out-of-limits aft center of gravity. Instead of the nose pitching forward, as would be the case for an airplane within allowable CG limits, the aft CG would pull the tail down and it would go into the ground tail first. The impact as shown in the video is that of an airplane that is likely within center of gravity limits.

The airplane that crashed at Bagram had already flown one leg with the load onboard with no problem. No additional cargo had been loaded and the load and tiedowns were reported to have been inspected at Bagram, probably by the company loadmaster who was on the airplane. Exactly what the cargo was, other than that it included five military vehicles of some kind, and how it was secured has not been released to the public. (Some have speculated that the fuel load might have put the airplane out of limits, but load planning is normally for zero fuel, which will keep the airplane within limits regardless of how the fuel is loaded.)

There are two ways to load vehicles into an airplane. One is to simply drive them on board and then secure them with chains or straps. The other is to position them on aluminum cargo pallets and then secure the pallets to the airplane, either with chains or straps or with locks. (There is information available that indicates that in order to load vehicles onto the 747-400, they have to be placed on pallets.) Cargo restraint requirements for an aft direction call for 1.5Gs, or one and a half times the weight of the item divided by the strength of the chains or straps. For example, a vehicle weighing 20,000 pounds would require 3.5 10,000-pound chains or 7 5,000-pound straps. However, tiedowns are required to be attached in pairs, so four chains or eight straps would be required. (Tiedown requirements for a forward direction are 3Gs, 2Gs are required for vertical restraint and 1.5Gs for lateral. There is a 4.5G requirement for vertical down, which is taken care of by the cargo compartment floor.) On airplanes where passengers are carried forward of the cargo, it must be restrained for 9Gs to protect the passengers in the event of a crash.) Incidentally, the FAA certification requirements for a transport category airplane are only for 2.1-3.8 positive Gs and for 1.5Gs for aft or lateral, and only 1G for negative.

Each tiedown chain, device and strap is actually rated to a tensile strength of 1.5 times its rated strength. The amount of actual restraint is determined by the angle of the attachment, with the maximum strength attained in a straight line. This US Army pamphlet will tell you all there is to know about cargo restraints - US Army cargo tiedown procedures. The information contained within this pamphlet is for military requirements. FAA requirements may not be the same. For example, the FAA allows the use of straps to secure items that the military requires the use of chains.

It is important to understand that the forces experienced during takeoff are actually acceleration forces, although they are expressed as Gs. The amount of the actual G force will depend on how rapidly the airplane accelerates, with faster accelerating airplanes producing a higher acceleration force. Because transport category airplanes certified under FAR Part 25 are only certified to 1.5Gs in an aft direction, that is the most that will be achieved. In reality, however, the force will be much less. The actual G force will depend on how long it takes the airplane to accelerate to takeoff speed and what that speed is. The acceleration force for large transport aircraft will be far less than for a high performance jet fighter or even for a corporate jet. For example, when NASA was still operating the space shuttles, the G forces experienced during a launch was only 3Gs. A Boeing 747 or Lockheed C-5 will experience only a fraction of a G during takeoff roll, probably less than .5G, which is the most likely time for a load shift to occur.

When observing the video of the 747, it is important to understand that when an airplane stalls, both wings may not stall simultaneously. When the airplane stalls, it will roll in the direction of whichever wing stalls first. When the other wing stalls, it will roll in that direction. An actual stall, sometimes referred to as a "deep stall," is not the same as stalls induced by pilots during training. While students in light trainers are instructed to take the airplane all the way to a full stall, pilots training in high performance airplanes are taught to initiate a stall recovery at the first indication of a stall, which may be the advent of the stick shaker on airplanes so-equipped. Stick shakers cause the control column to vibrate whenever the airplane approaches a stall. They are installed on airplanes that have violent stall characteristics. In fact, some airplanes not only have a stick shaker, they are also equipped with a stick pusher, which overrides the pilot's input and pushes the nose forward as the airplane approaches the stall. Stick pushers are installed on airplanes that have demonstrated violent stall characteristics. For example, some airplanes may actually roll inverted when they stall. They may only be certified with the addition of a stick pusher.

Wind shear is a very dangerous meterological phenomena, and there is more than one kind of wear shear. A search of the NTSB database revealed more than 600 accidents and incidents in which the probable cause was determined to have been due to wind shear (by contrast, only one was found to have been caused by a load shift.) A wind shear is wind at one altitude or position coming from one direction or velocity and from another direction or velocity only a short distance away. For example, it is not uncommon for the wind to be from one direction at a specific velocity but to be from an entirely different direction or velocity at a different altitude. Wind shear can also occur when the wind suddenly decreases or increases. A sudden loss of speed can cause an airplane to stall unless the pilot immediately compensates by increasing power. FAA and manufacturers procedures call for pilots to increase their approach speed by a factor of half of the reported gusts, usually up to a maximum of 20 knots, when flying an approach in gusty conditions. (The 20 knot maximum is to avoid increasing landing distance.)

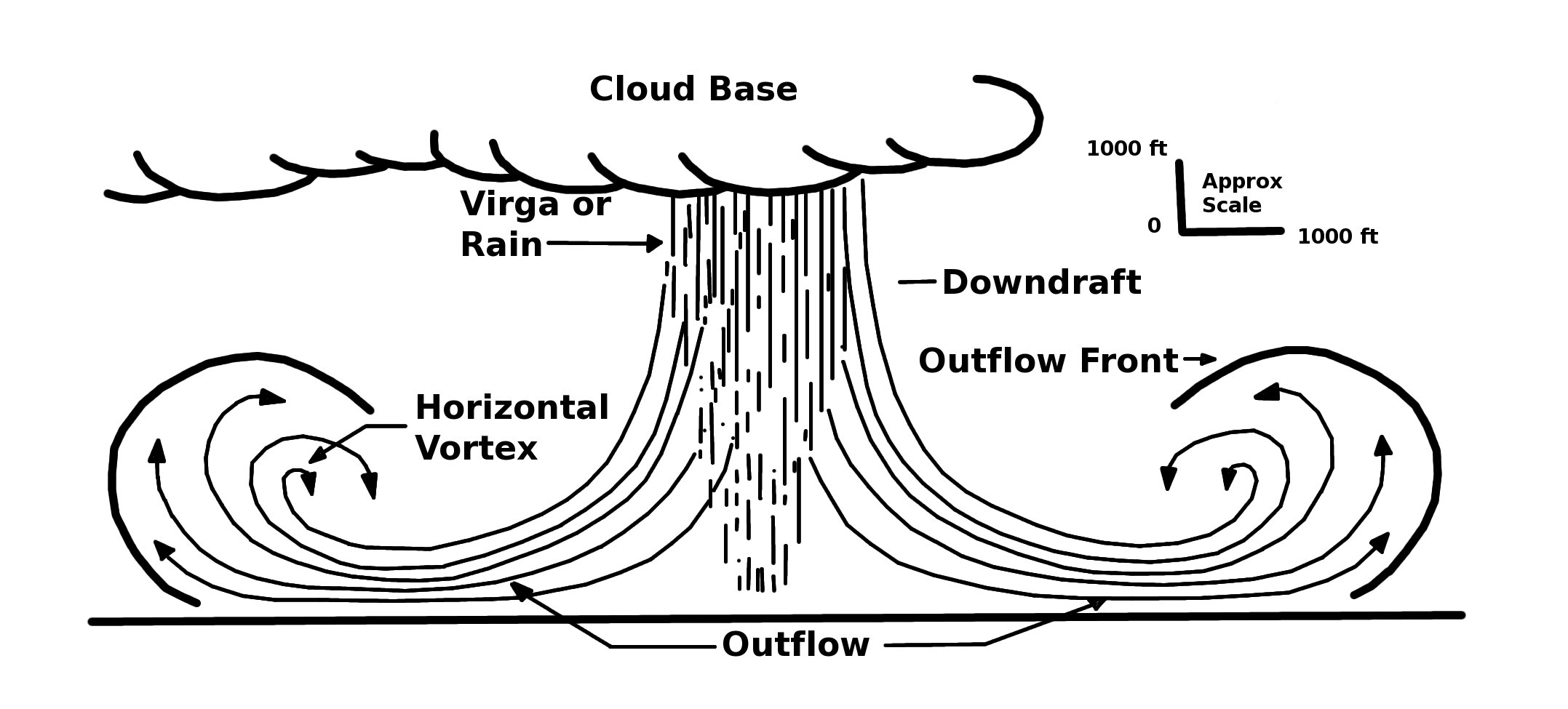

There is another kind of wind shear that is deadly, a vertical wind shear. Vertical wind shear is caused by updrafts and downdrafts and is often associated with thunderstorms. In 1975 a Boeing 727 was on approach to JFK airport when it encountered a sudden downdraft, now called a downburst, that literally forced the airplane into the ground. Other fatal accidents caused by downbursts occured at Dallas-Fort Worth and New Orleans. The New Orleans crash was right after takeoff while the DFW crash was on approach. Dr. Theodore Fujita identified a previously unknown phenomena that was he identified as a downburts. Meterologists began paying close attention to downbursts and determined that they can be of differing scale and vertical velocity. They were divided into "macrobursts," where the width is 4 kilometers or greater, and "microbursts," where the diameter of the shaft is less than 4 kilometers. Some microbursts may be as little as 50 yards (150 feet) wide. Here is one NOAA paper that defines a microburst. Although microbursts occur in rain shafts, in many cases the burst of wind is "dry", meaning that there is no rain at the surface. This is a paper on microburst that was published by NOAA in the late 1990s. Unfortunately, some of the referenced figures are no longer on the server. There are graphics in this paper that show what a dry microburst is like. This is another NOAA online pamphlet about microburt.

After the New Orleans crash, airline and manufacturer test pilots conducted simulator tests using various models of known microburts to determine if it was possible to survive them. Initially, the New Orleans microburst was found to be unsurvivable, but the test crew discovered that by departing from normal takeoff procedures and raising the nose to a high angle while leaving the landing gear and flaps in whatever position they were in, a pilot might be able to fly out of it. However, the high nose angle brings the airplane very close to a stall. While instructing in a simulator and during sessions when I was flying, I discovered that many pilots were often unable to accomplish a successful procedure the first time they tried it. In many cases, the airplane would stall. We had several different models of microbursts and other wind shear in our simulator, all based on previous accidents, and some were easier to overcome than others.

Depending on where the airplane is in relation to the center of the microburst, the pilot will experience different effects. For example, a microburst striking the ground in front of the airplane will initially produce an increasing headwind - the winds will deflect outward when they strike the ground - followed by an extreme downward pressure on the airplane and then a tailwind and corresponding loss of airspeed as the airplane passes through it. Microbursts have been recorded as high as 168 miles an hour - straight down - which would be disastrous for any airplane that happened to be caught in it. In the case of a dry microburst, there may be no indication at all of its presence until it strikes the ground and causes a sudden curling dust and debris. A wet microburst will be accompanied by curling rain at the surface.

A pilot may not realize he is experiencing a downburst until it is too late. The first indication may be a sudden change in airspeed, either increasing or decreasing, or it may be a failure of the airplane to climb after rotation, followed by an uncontrollable descent. The only possibility of escaping from a violent downdraft is to increase pitch enough to cause the airplane to start to climb - while avoiding a stall. Basically, it's like balancing on a basketball. In the case of an airplane the size of a 747, it is possible that a crew might feel the tail of the airplane being pushed down if the force of the wind struck the rear fuselage.

Fortunately, there have been no aircraft accidents in the United States attributed to a downburst since 1994 when a US Airways DC-9 crashed at Charlotte, NC while attempting a go-around. The airplane actually stalled because the pilot failed to increase power. However, just because there have been no accidents due to downburst conditions doesn't mean that they don't occur. It only means that no airplanes have gotten in the way of one and were unable to recover. (An encounter with a downburst that doesn't produce an accident or incident will not be reported.) After all, the fatal accidents caused by downbursts are spread over a period of more than a decade. They were well known because of the numbers of fatalities involved.

Did a microburst cause the Bagram crash? It is a definite possibility.

Mechanical Problems/Malfunctions

Other possibilities that can lead to a possible stall would be a malfunctioning elevator/stabilizer trim or a malfunction in the operation of the elevator/stabilizer operating system. The Boeing 747-400 flight controls are hydraulically operated and some, including the elevator control tabs, are electronically controlled. They have no manual reversion.

There is also the possibility of a failure of one or more engines. While multiple engine failures are rare, contaminated fuel can cause successive failure. Compressor stall and corresponding loss of power can occur, particularly if the airplane is placed into a high angle of attack and airflow into the engines is reduced.

In short, there are a myriad of possibilities for mechanical failure that can cause an airplane to stall.

Crew Experience and Crew Error

As with all accidents, there is always the possibility of some kind of crew error. The cause of the crash may turn out to be as simple as that the pilot got the nose too high on takeoff and the angle of attack increased to the point that a wing stalled. Another possibility is that the airplane wasn't properly configured for takeoff for Weight, Altitude and Temperature.

Although the US National Transportation Safety Board and the Federal Aviation Administration sent personnel to Bagram to assist with the investigation, as did Boeing, the accident is being investigated by the Afghanistan Ministry of Transportation and Aviation and the report will be issued by them. (Note - Although the Afghan government began the investigation, in October 2014 it delegated responsibility to the NTSB. No accident report has yet been released. Here is the preliminary report.

There really is no reason to speculate, and there probably wouldn't be so much speculation if the accident hadn't been captured on a camera for all the world to see.

Home to Return